Discover how ENCY is transforming the world of CNC and robotic manufacturing with an all-in-one solution. This video introduces the platform’s vision and core capabilities, setting the stage for the features ahead.

CAD/CAM ecosystem built to transform the way you work

Advanced CAD/CAM bundle: CNC and robot programming, shop floor simulation, and cloud collaboration. Faster CAD-to-part turnaround with local support.

Products

ENCY CAM

ENCY Robot

ENCY Tuner

ENCY Clouds

ENCY: CAD/CAM for a new generation

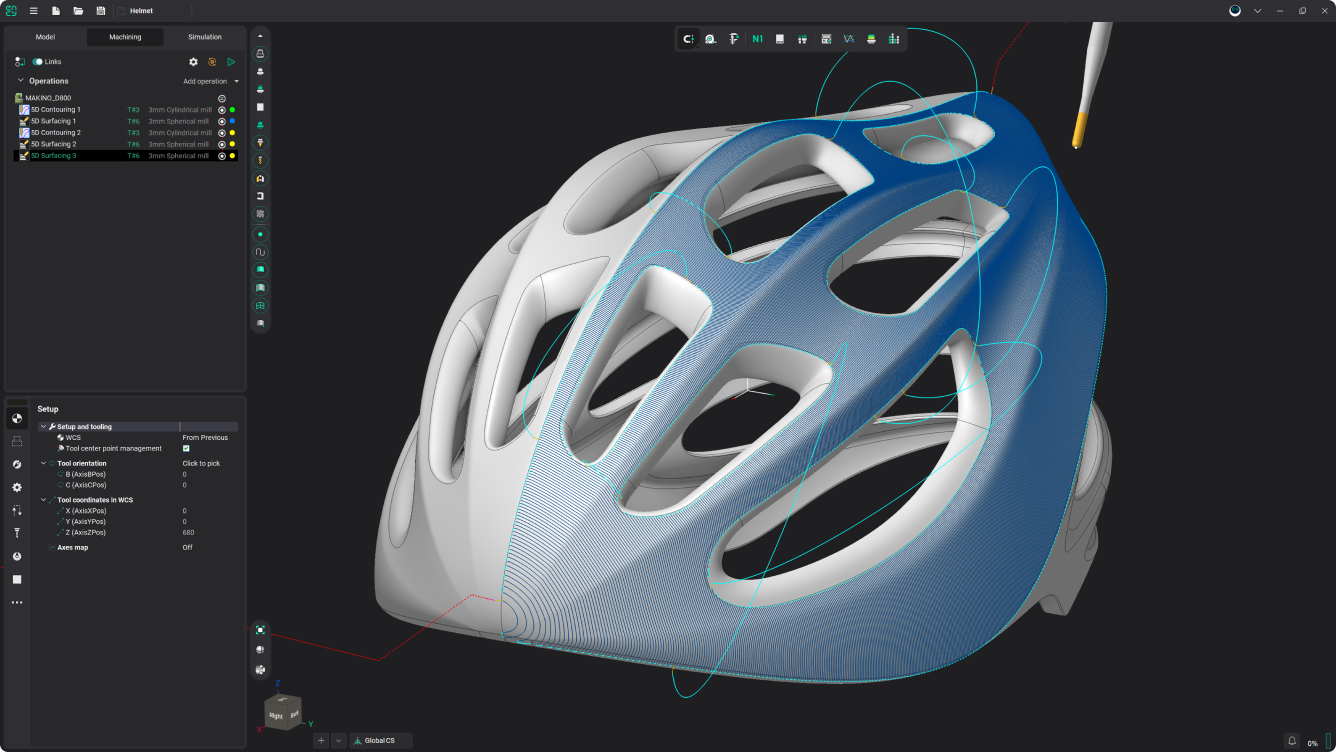

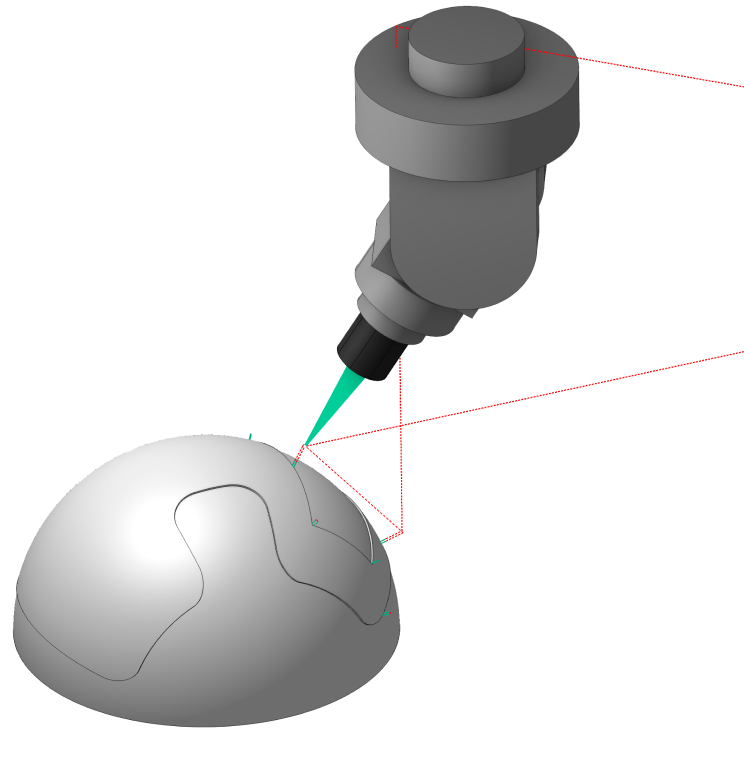

Delivering sophisticated CAM technology with an intuitive user interface and natural workflow

Why ENCY: What makes our software different from other CAD/CAM systems?

Let’s highlight the key factors that make ENCY stand out from other solutions available on the market.

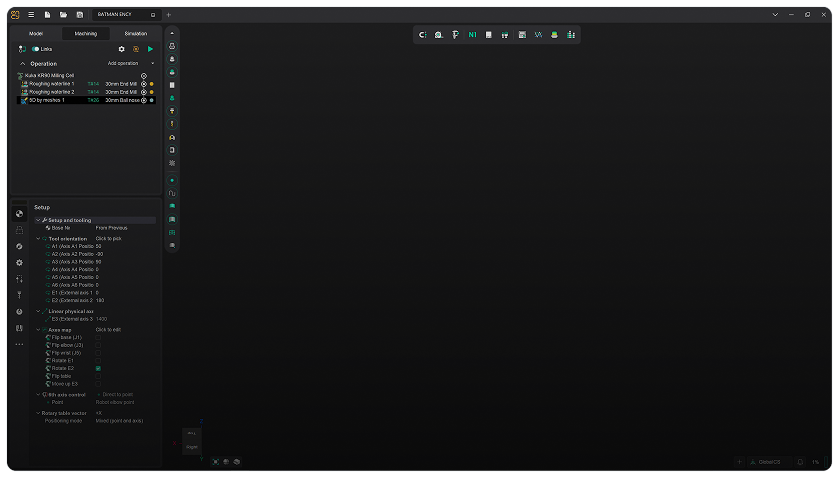

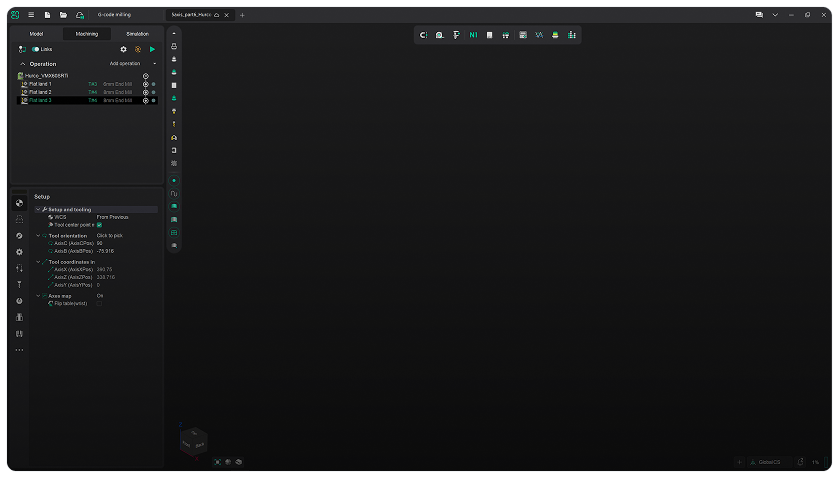

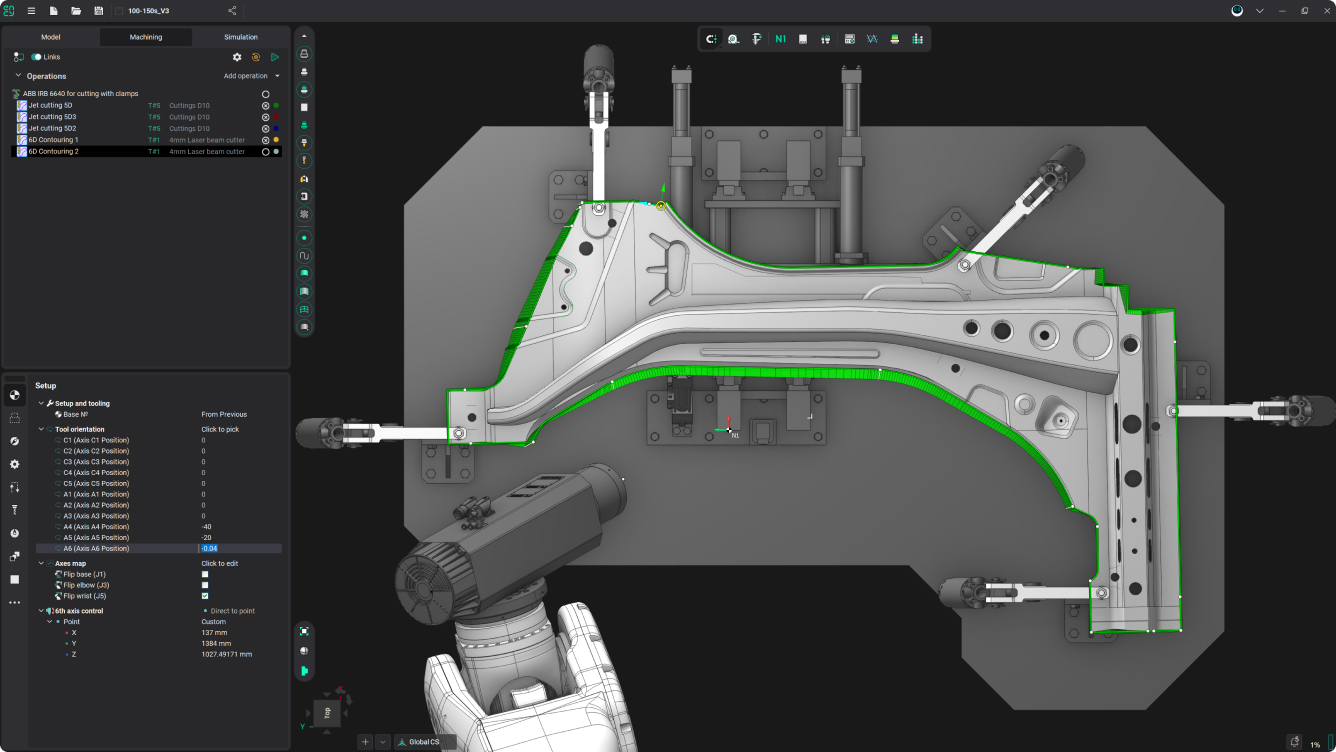

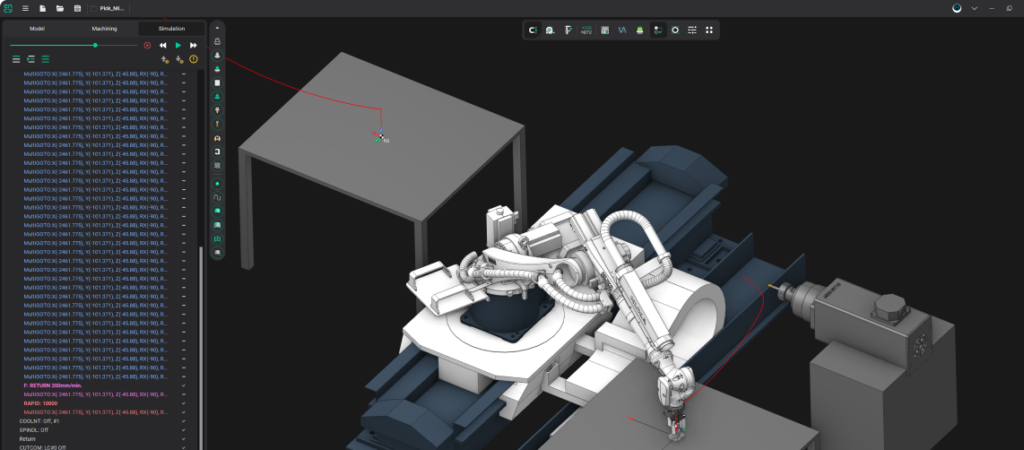

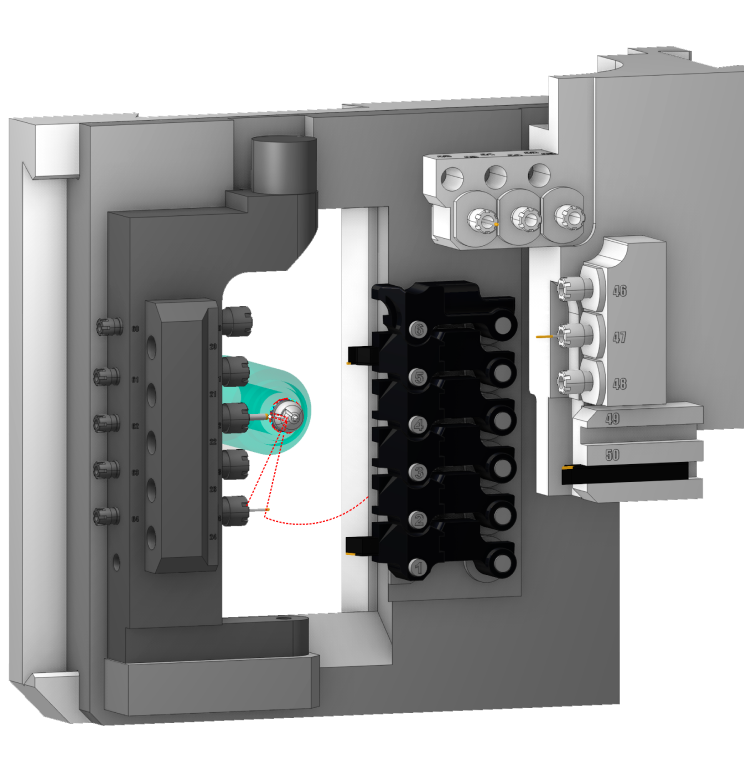

With ENCY, CNC and robot programming are seamlessly integrated into one intuitive interface. No extra software — just built-in CAD, CAM, simulation, and post-processing for a streamlined, all-in-one workflow.

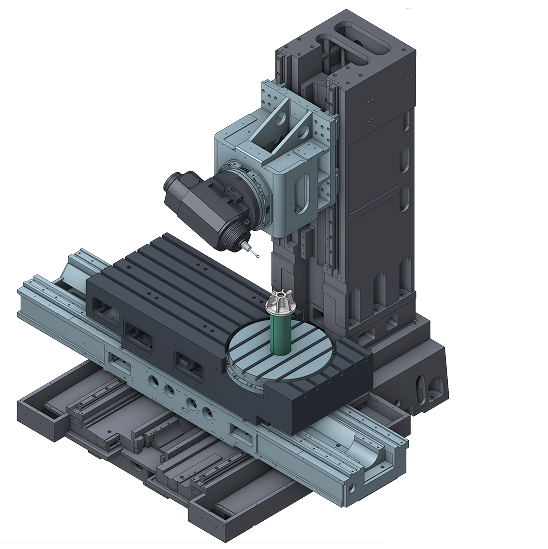

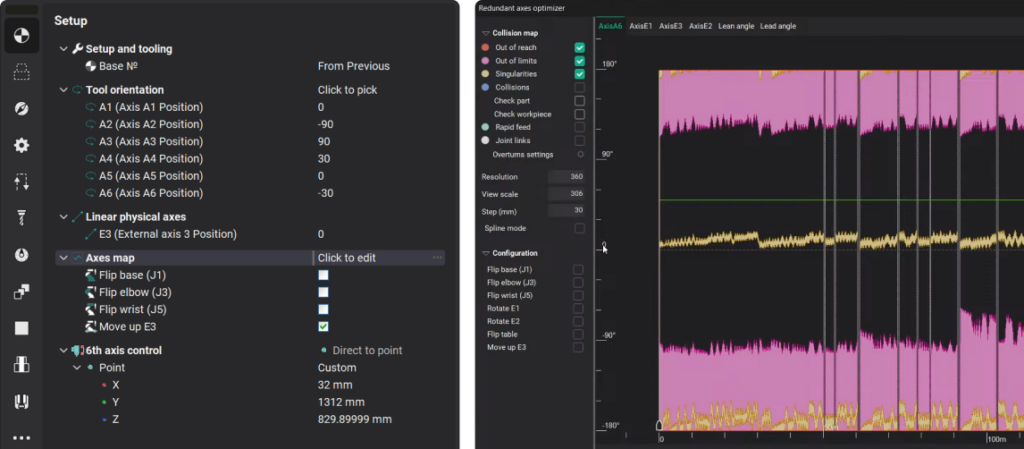

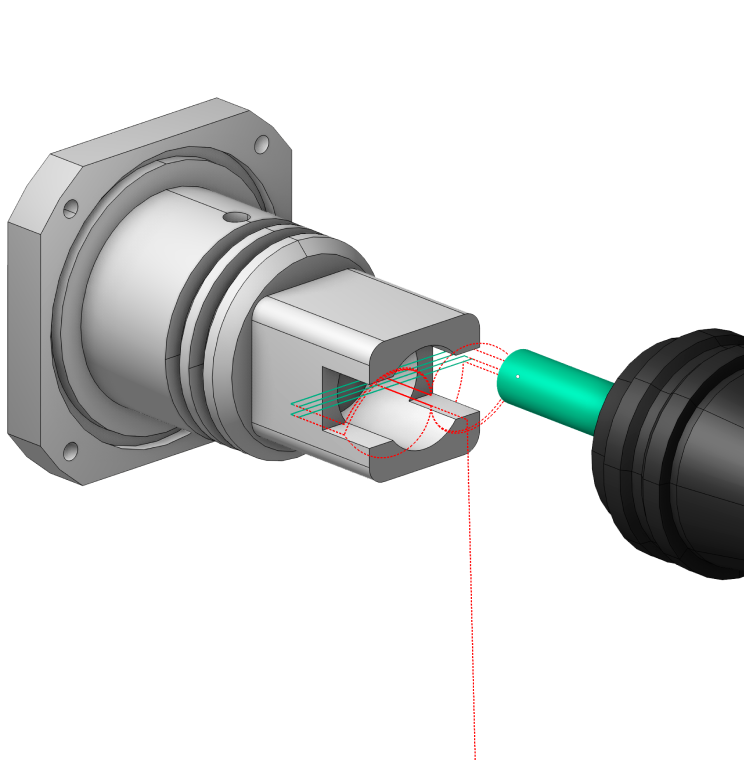

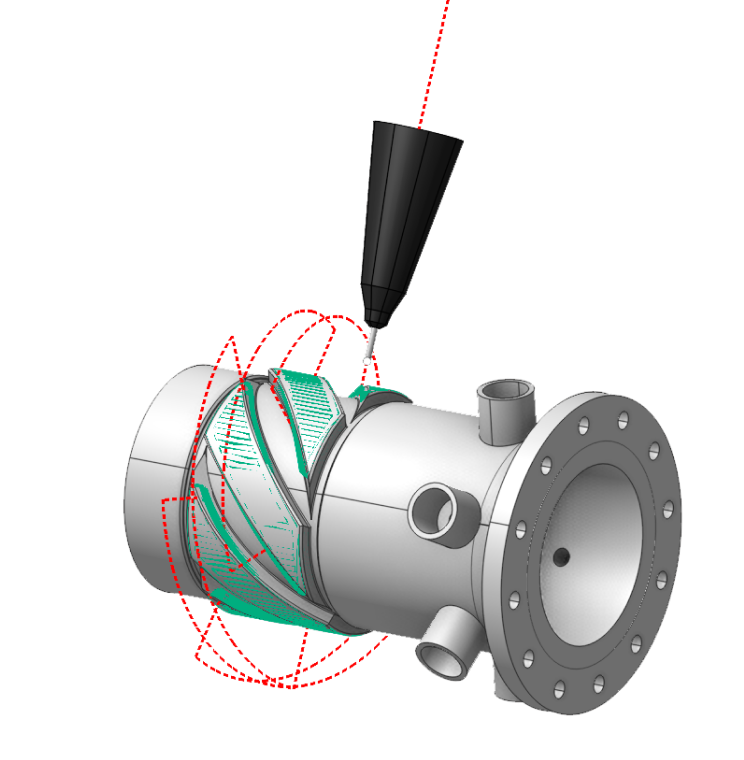

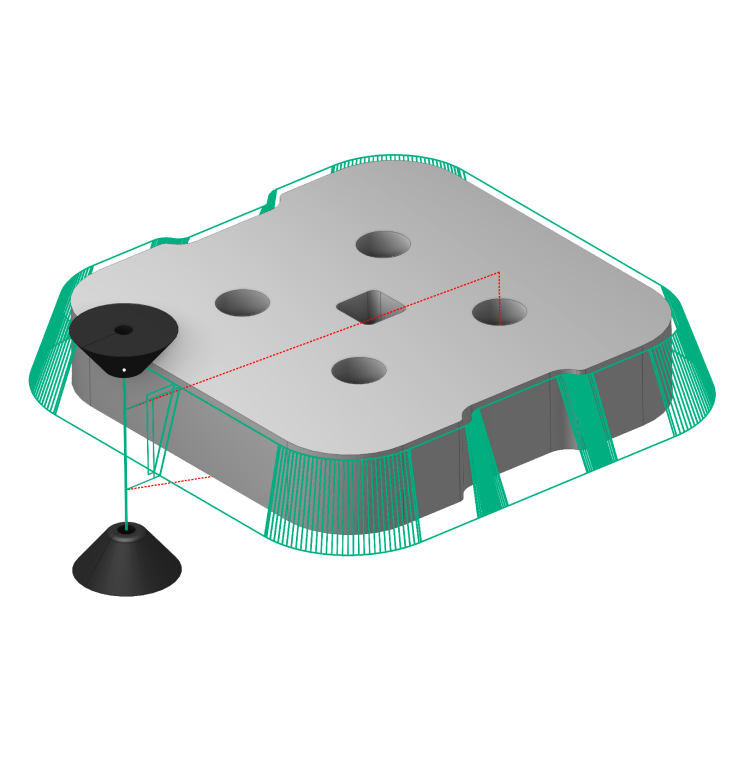

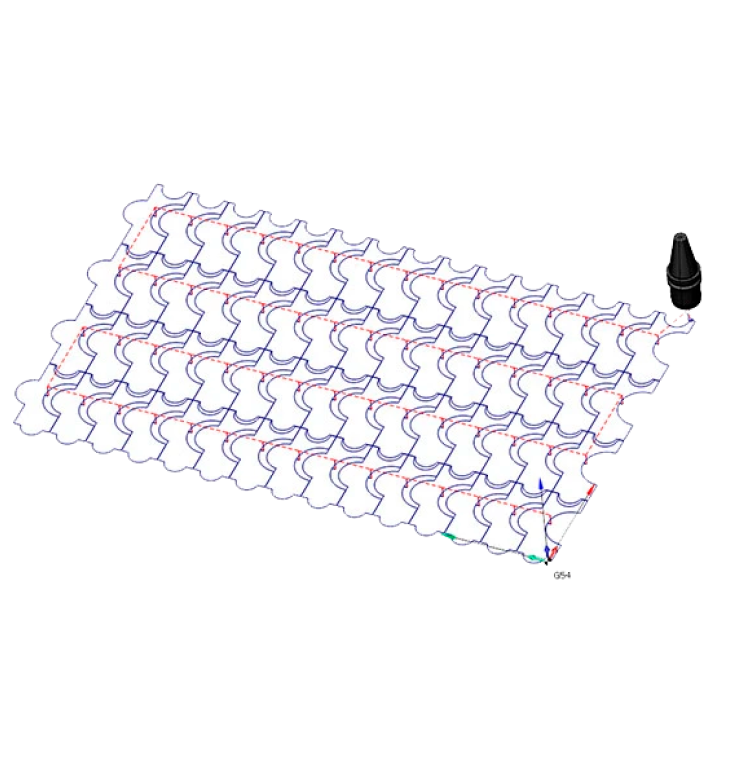

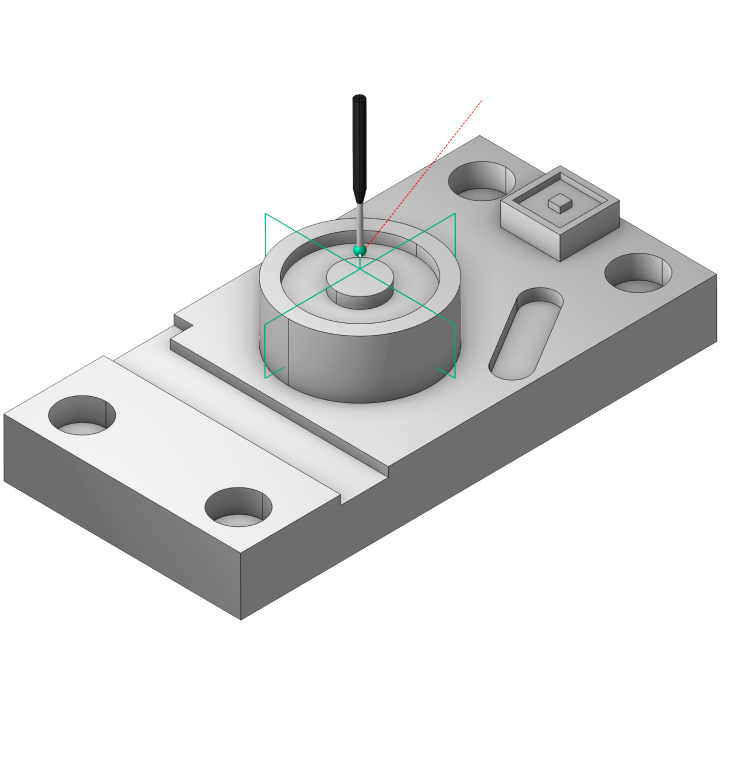

Unlike most CAD/CAM systems, ENCY integrates the machine’s digital twin from the start. Its Machine Awareness technology detects issues early, optimizes toolpaths in real time, reduces programming loops, and streamlines multi-axis machining with automatic transitions and realistic virtual setups.

ENCY is built entirely in-house, allowing us to innovate freely, respond to user feedback, and avoid costly third-party licenses—delivering a more efficient, cost-effective solution for your business.

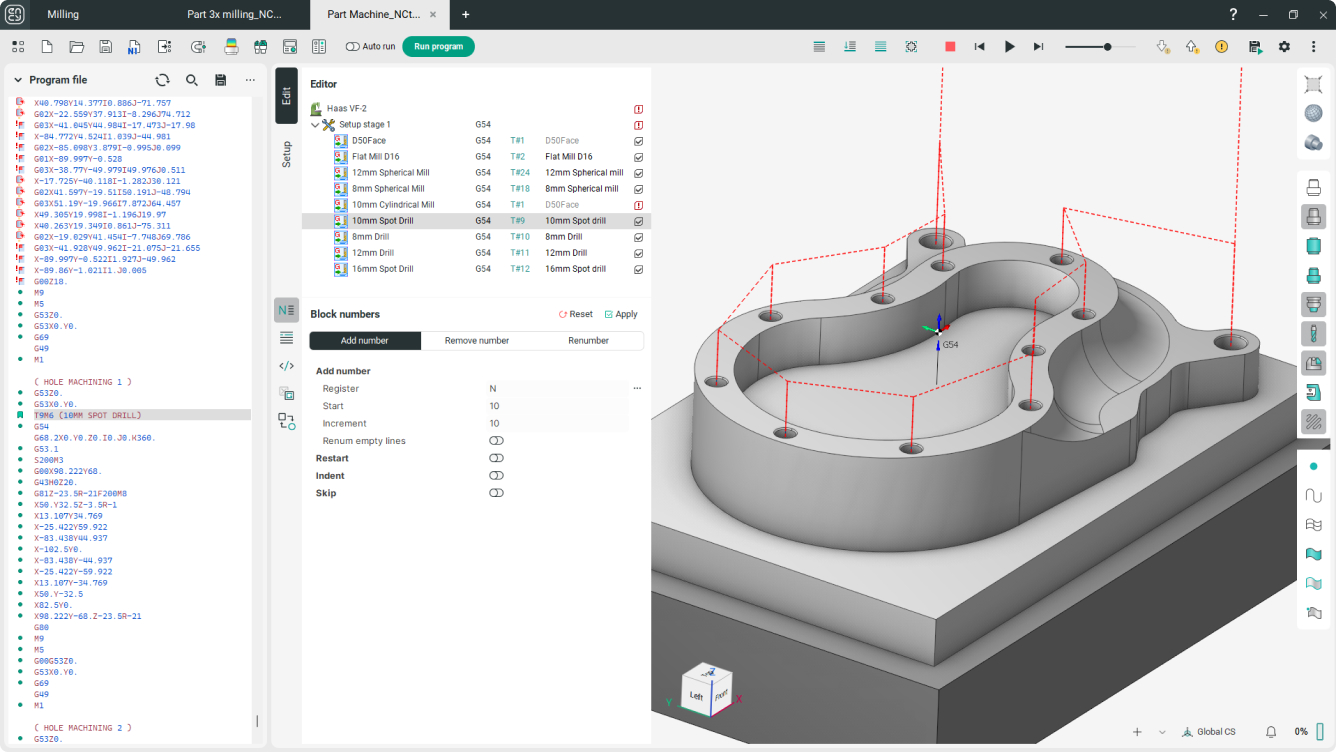

ENCY’s modern, streamlined UI keeps CAD, CAM, and simulation intuitive. With a clean layout, sleek icons, and a dark theme for comfort, it enhances productivity. Smart hints and multi-tab support make programming faster and easier for all skill levels.

ENCY goes beyond a powerful platform with next-level interactivity. Adjust machining parameters on the fly, control virtual machines seamlessly, and even edit toolpaths interactively—all with instant visual feedback for a faster, smarter workflow.

ENCY’s proprietary simulation engine delivers precision and speed with Solid and Voxel Simulation modes. Fully integrated, it provides real-time stock updates, full machine visualization, collision detection, and G-code verification—enhancing the entire machining process.

MachineMaker simplifies building CNC and robot digital twins—no programming needed. Import 3D models, define kinematics, and fine-tune parameters with interactive tools. Seamless integration with an online component library makes virtual machine creation faster and more precise than ever.

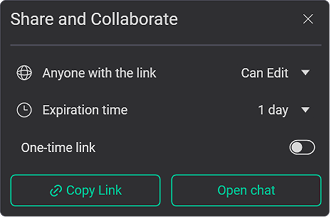

This platform features hundreds of pre-made machining projects, shared by ENCY users and dealers. With this library, you can: store your machining projects in a private cloud; easily share files with colleagues or the entire ENCY community; use smart search filters to quickly find relevant machining examples.

ENCY Clouds revolutionizes manufacturing teamwork with built-in chat, real-time file updates, screen sharing, and instant support—eliminating endless calls and messages. As part of the ENCY X ecosystem, it streamlines collaboration across users, suppliers, and industry experts.

Robust CAD/CAM platform for both worlds: CNC and robots

Proprietary platform: Powerful CAD/CAM for CNC and robots. Secure, content-rich, API-enabled, and collaboration-ready.

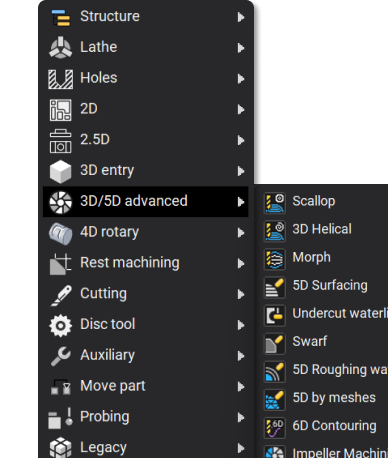

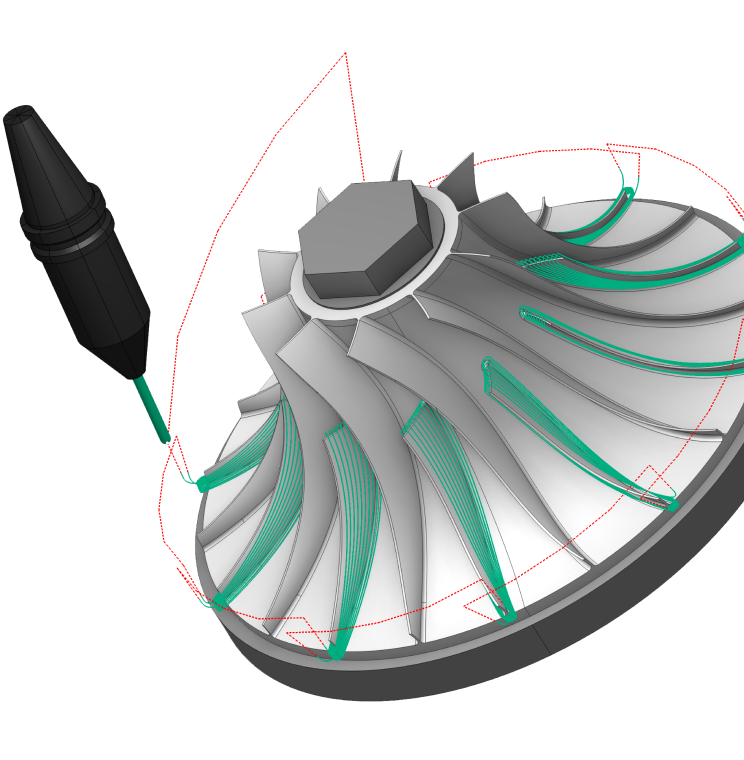

A wide range of machining strategies from 2D to 5D

Interactive

Parametric CAD

NC-code simulation and verification

State-of-art interface

Crisp at 4K screens

Open API

Technological independence

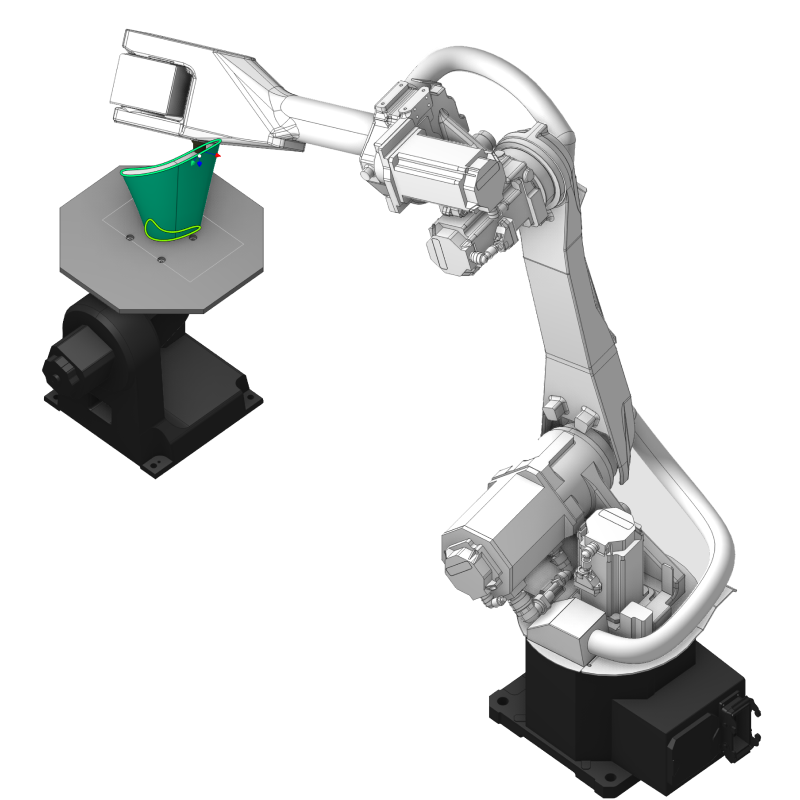

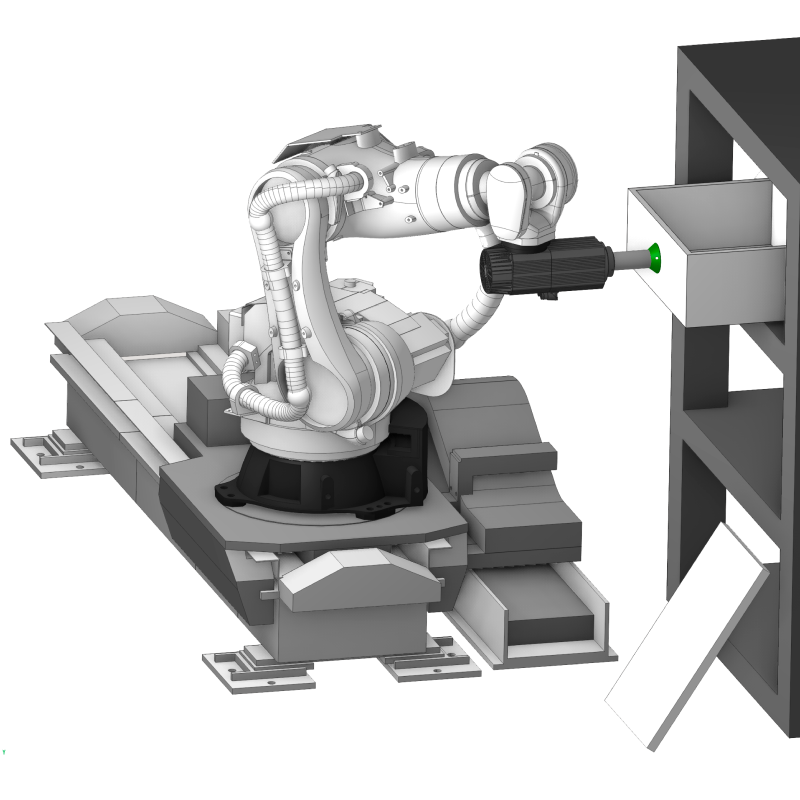

Comprehensive toolset for robot kinematic management

Full robotic cell simulation

Introducing ENCY X: CAD/CAM ecosystem

What is ENCY X?

A new CNC machines and robots programming experience

ENCY Software CEO explains:

The concept behind ENCY X is straightforward. We evaluate the broader context in which a CAD/CAM programmer operates, automating workflow elements beyond the software’s direct use.

We discovered that, aside from NC-code creation, communication and data exchange are the most time-consuming tasks. To address this, we developed ENCY Clouds, a cloud-based collaboration tool combining an online chat and a project library, seamlessly integrated into our software. This reduces clicks and ensures a smooth workflow.

All our CAD/CAM products—ENCY, ENCY Robot, and ENCY Tuner—are now connected through ENCY Clouds, forming the ENCY X platform. This creates a transparent environment for programmers, operators, experts, and engineers, providing ultra-fast communication and data exchange. As a cherry on top, we’ve injected an AI assistant into the collaboration chat to enhance productivity.

No more emails, cloud drives, bloated hard drives, paper, or manually sending photos and videos to analyze issues.

We are excited to welcome CAD/CAM programmers to the new CNC machines and robots programming experience.

Ready to embark on your ENCY journey?

CNC Capabilities

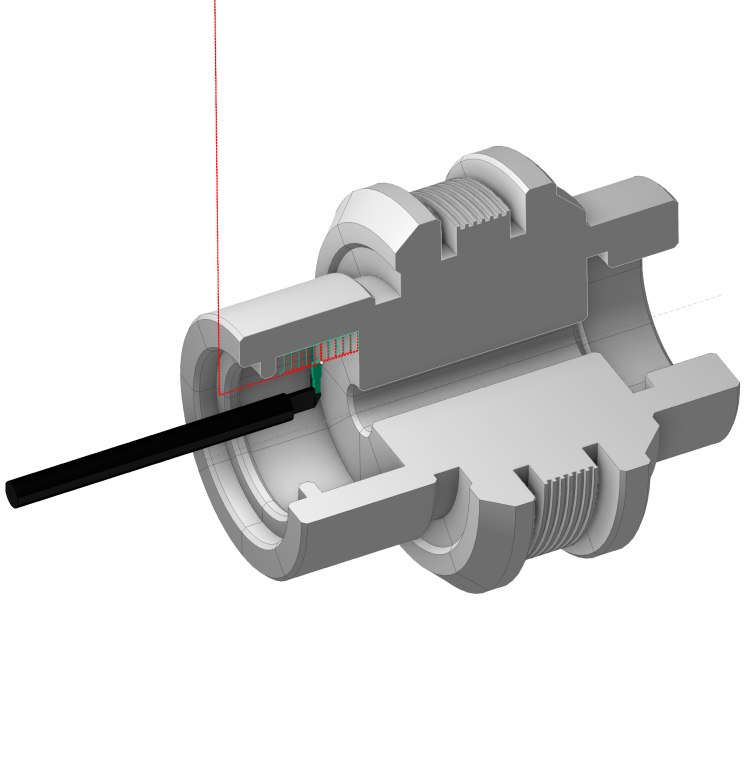

2.5x and 3x mill

Production of molds & dies and any other parts on a 3-axis milling machine

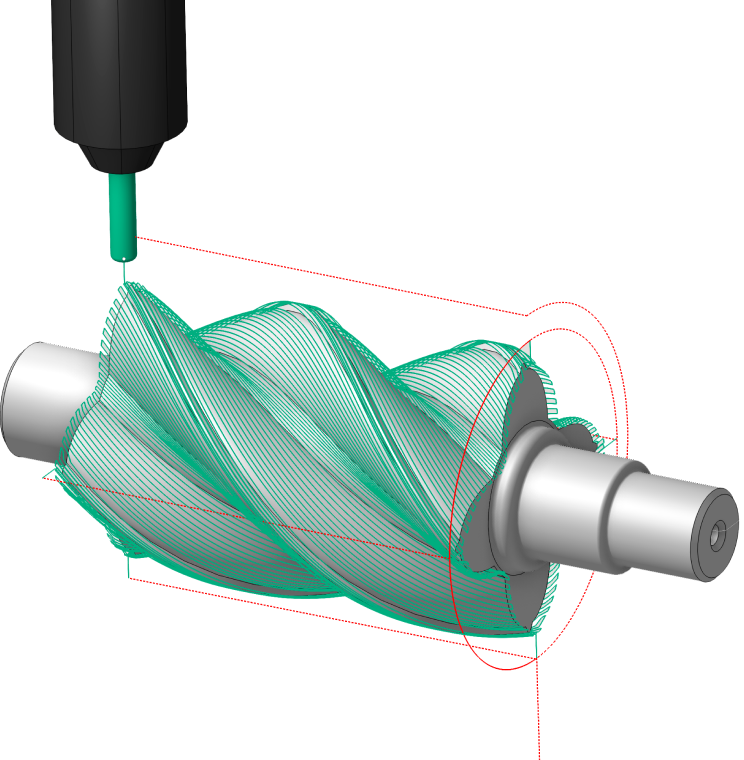

Rotary

Production of screws, blades, gear wheels, balusters

Lathe

Probing cycles for Milling and Lathe Machines

Robot Capabilities

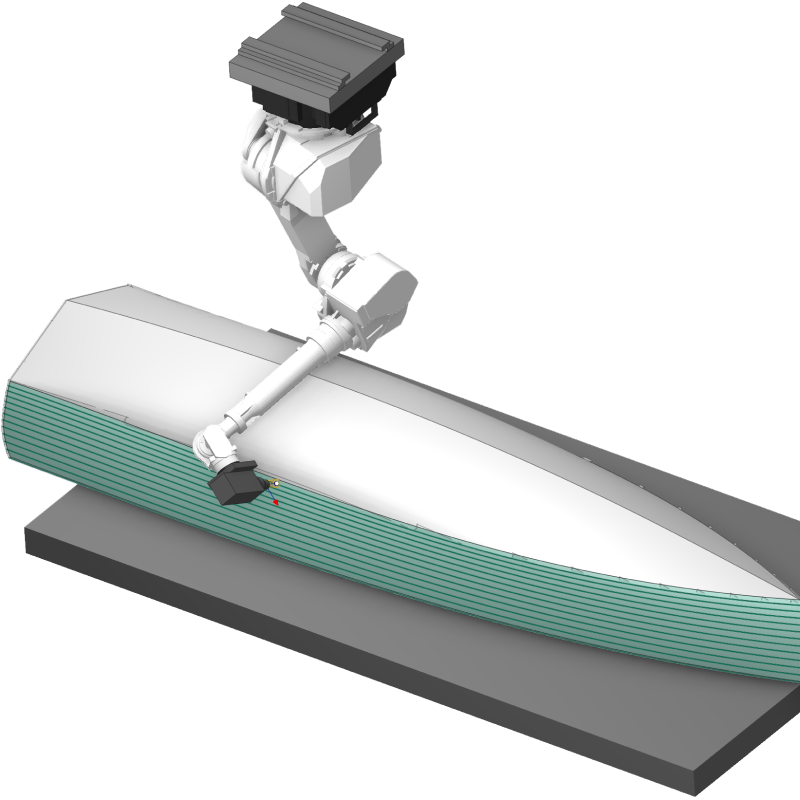

3—5D milling with redundant axes support

Robot cutting

Miltiaxis cutting with precise tool vector control

Additive

3—5D cladding with advanced layer thickness control

Robot welding

Simple easy-to-use solution for welding programming

Sculpture/Stone

Stone roughing, disk tool, advanced 5D finishing for mesh models

Pick and place

Collision-free automatic pick-and-place

Spray painting

Simulate and test your painting on your PC

Polishing

Tool-to-part and part-to-tool supported

Connect with your local ENCY dealer in United Kingdom

Get personalized support and tailored solution. Our representatives are ready to help you maximize ENCY’s potential for your business.

ENCY Representative in the UK

Official ENCY SOFTWARE Representative in United Kingdom

CNC Robotics Ltd

Official ENCY SOFTWARE Dealer in United Kingdom

Unit 5 Galgate Dr, Bootle L30 6UZ, UK

No results available

Reset